CreateBoat Example

Stephen M. Hollister

New Wave Systems, Inc.

www.newavesys.com

This is a beginners

tutorial to introduce you the basic functions and features of our ProChine

program (also applies to ProBasic and ProSurf). This can be the first tutorial

you see before using the program for the first time. We will give you

step-by-step instructions that will allow you to try out the program and see

what it can do. We assume that you are

a little bit familiar with how to use the computer and how Windows programs

work in general.

Start by double-clicking

the ProChine (or ProBasic or ProSurf) icon on your Windows desktop. You should

see the following screen with four blank windows (after the startup information

screen has been shown).

Each window will show a

different view of the boat: side (back) or profile view, top (or bottom) or

plan view, right or section or bodyplan view, and finally the 3D or perspective

view. These views sometimes confuse people since the profile view of the boat

is called either the front or back view, depending on which direction the bow

of the boat on the screen. Also, the plan view is called the “bottom” view (as

opposed to the top view) because we like to keep the bow of the boat pointing

to the right. (Have you ever noticed that boats only seem to go to the right?)

Don’t get too confused by the labels of the views. Part of our view labeling

scheme is based on what the general purpose CAD programs use.

The next change I want

to make is to eliminate 3 of the 4 view windows. Some people like to see all 4

views of the model at one time, but I like to see just one view, but at maximum

size. I did this by clicking on the ‘X’ in 3 of the 4 windows. Then I maximized

the remaining window. If I want to see a different view than the one I have on

the screen, all I have to do is pick the appropriate button on the toolbar.

Speaking of the toolbar, it is shown below and some of the functions are

explained.

![]()

As you can see, it looks

like a standard toolbar with the command or function pull-down menus located at

the top. All of the file and print options work like any other Windows program

so they will not be discussed here. If you want a brief description of the

toolbar functions, just hold the cursor over the toolbar “button” and a label

will be displayed.

The most important

command on the toolbar is the counter-clockwise arrow, which is the Undo

command. Anytime you change the geometry of the boat and wish to undo the

change, just pick on this button once. You can go back up to 25 steps and you

can show a list of the previous Undo commands using a command in the View list

of commands. The ‘H’ buttons with the circular arrows are for hiding and

un-hiding geometry on the screen. This is important when your boat gets

complicated and you want to temporarily hide portions so that you can see what

you are doing. The 4-direction arrow button is selected when you want to move

the “edit” points that control the shape of the boat (Move Point). This is the

most common command you will use to change the shape of your boat.

Please note that most of

the commands in the program are “mode” commands. This means that the command

you picked will stay “ON” until you select another command. This means that if

you pick the Move Point command, you can continue to move any point on the

model until you pick another command.

You do not have to first select the geometry or entity before you can

edit its shape.

The tool bar buttons

that look like (or at least are supposed to look like) a boat’s profile, a

boat’s top view, and a boat’s section view are used to change the view of the

boat in the current window. The 3D button puts the current view into the 3D

perspective view. The 3D button is followed by 4 buttons that will change the

view of the boat in the 3D view; either up or down or rotate left or rotate

right. If you switched the program’s display to just one window, you will use

these buttons to change the current window to display that view.

The ‘K’ buttons are use

to display and control the curvature or “K-curve” on the boat’s curves and they

are used to magnify the fairness of the hull.

You will have to see the special tutorial on fairing and smoothing to

find out more about these commands.

However, the toolbar

buttons that look like hand-held magnifying glasses are important. The one that

looks like a plain magnifying glass is used to “zoom” in on a portion of the

window that you are interested in. It works just like many other CAD programs

in that you will press the left mouse button and drag a zoom box to define the

area you wish to enlarge. The magnifying glass with the line through it is used

to reset the view. It will resize the display to maximize the view of the boat

in the window. You will need to use this command many times.

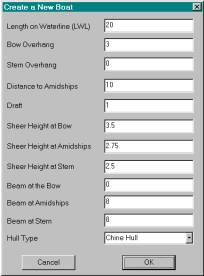

OK, let’s get started

the easy way by using the CreateBoat command in the program. This command,

located in the File set of pull-down commands displays the following dialog box

and allows you to define a starting shape for a boat that uses your own

principal dimensions. Go ahead and select this command and you should see this

input dialog box.

Note that the values are

filled in already. This is done for two reasons. One, so you can see what an

example boat’s values look like and two, so you can pick the OK button and

create a sample boat without having to come up with your own values. There are

many times you might want to quickly create a test boat so that you can try out

some things… like now. So, pick the OK button and you will see the following

screen if your current view is the profile view of the boat. This command

creates a starting shape of the boat using 3 NURB surfaces: one for the bottom

surface below the chine, one for above the chine and one for the deck.

Initially, the deck surface is turned off. Initially, there is no transom

defined. That can be added later, if needed. This is a considered to be a 3D

geometric surface model of the boat.

The first thing I want

you to do is to use the toolbar buttons to look at all of the 4 views of the

boat.

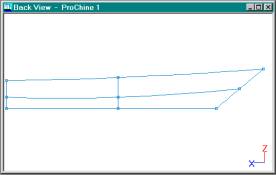

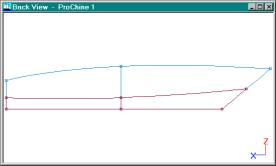

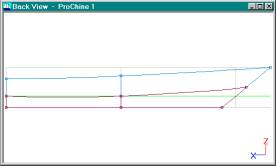

When you pick the side

view toolbar button, you should see this view.

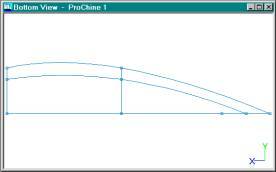

When you pick the top

(or bottom) or plan view toolbar button, you should see this view. If you want

to be picky, then this is a view of the bottom of the boat and what is drawn is

the starboard half of the boat. Note that the program assumes that the boat is

symmetrical about the centerline and all you have to do is to design one-half

of the boat.

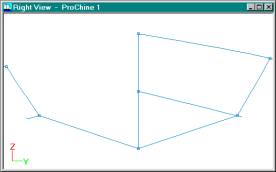

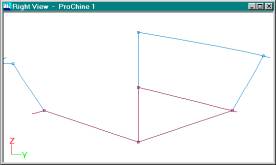

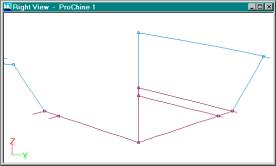

When you pick the right

or section view toolbar button, then you will see this view. This may look

rather odd, but it is a common sight for boat designers or naval architects.

The traditional display of a boat in cross-section or bodyplan view shows the

forward sections (in front of amidships) on the right of the centerline and the

aft sections (aft of amidships) on the left of the centerline. The reason this

is done is to clean up the display of the sections so that the aft sections

(stations or frames, if you prefer) do not overlay on top of the forward

sections. The bodyplan view takes a little bit of time to get used to, but it

does clean up the view. Perhaps not too much for this simple boat, but for

complex shapes, it can make a big difference. You can, however, turn this

“flip” option off or adjust exactly where along the length of the boat you can

flip the sections from the right to the left.

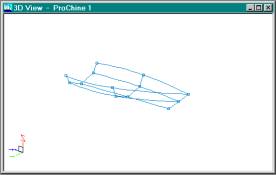

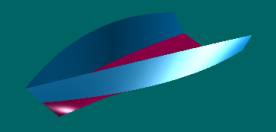

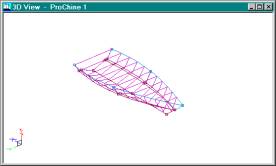

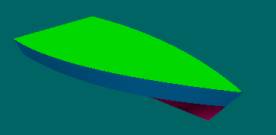

This view is displayed

when you pick the “3D” button on the toolbar. The program will display both

halves of the hull for viewing. Try using the “Z” rotate buttons and the “Up”

and “Dn” buttons to rotate the boat left and right and up and down.

Next, go to the “View”

set of pull-down commands and select the Render View-Open Render View command.

You should see something like this. You can also use the rotate buttons to

change the angle of the boat in this view. Note that you cannot edit the shape

of the boat in this view – perhaps in a future version.

[Note that we use the

OpenGL render display commands provided with all Windows systems. We have noted

that in some systems, this display might look incorrect or extra jagged. If so,

then go to the View-Render View-Screen Options dialog box and make sure that

the “Nurb Polygon Tolerance” input field is set to 15. If this doesn’t help,

then feel free to contact us.]

To leave the Render View

of the boat, just pick the ‘X’ in the corner of the window. You can re-display

the view at any time using the render command. For the next part of the

tutorial, you want to turn off the render display.

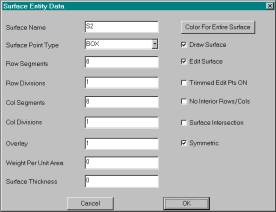

If you want to change

the color or some other attribute of a surface, all you need to do is to use

the “right” mouse button and click on any curve that represents any one of the

surfaces. The following surface attribute dialog box will be displayed.

I will not take the time

to explain all of these options, but they are used to control the options for

the surface you picked. If you pick the “Color” button, you will see a standard

Windows color selection dialog box where you can select a standard color or

create a unique color yourself. For this tutorial, I picked the bottom surface

and changed it to a burgundy-like color.

This is what it looked

like after going back to the Render View display. Remember, so far, we have not

changed the shape of the boat yet.

Before we go on, pick

the ‘X’ for this display and go back to one of the standard views of the boat.

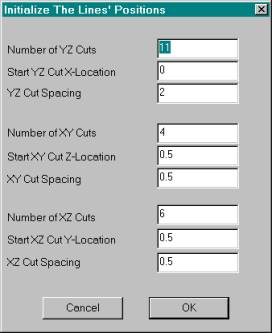

We will now define a set of stations, buttocks, and waterlines for the

boat. This is done with the

PlaneCuts-Initialize Lines command. (Select the PlaneCuts pull-down menu and

select the Initialize Lines command.) You should see the following dialog box.

This dialog box allows

you to define a set of stations, waterlines, and buttocks that you want to use

for the boat. These lines will form a starting set of lines for the boat that you

can add to or subtract from. Do not feel that you are stuck with this starting

set of lines. Often times, a designer might use a certain set of stations

during the design of the boat, but switch to a different set of “frames” for

building purposes. You can also add or delete lines from this list at any time.

For those getting a

little bit confused, keep in mind that our program uses NURB surface “rows” and

“columns” to define the shapes of all surfaces. The columns are kind of like

stations and the rows are kind of like diagonals. One of the biggest changes

from traditional hand drafting is the use of these NURB surfaces where you

control the shape with “rows” and “columns” and NOT stations, waterlines, and

buttocks. You can, however, display any of these traditional lines during the

editing process. For example, you can

see a waterline change shape while you edit a surface row or column, but you

cannot directly edit the shape of the waterline itself. The benefit of this

technique, however, is that you do not have to make sure that the three views

of the boat match up. The NURB surfaces are guaranteed to match up in all three

views.

Anyway, just pick the OK

button to accept the default lines for the default boat. [The default boat and

lines make it easy to play around with the program.] Next, select the

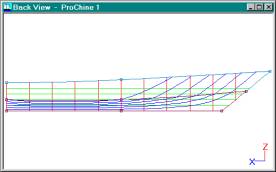

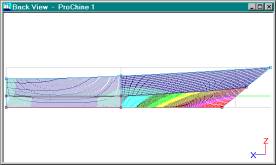

PlaneCuts-Display Lines-All Lines ON command to show the lines on the boat. For

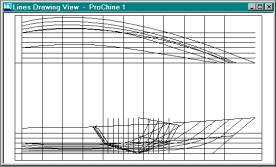

the profile view, you should see the following.

You can switch to the

other views to see the lines in those views. The green lines are the

waterlines, the red are the stations, and the blue are the buttocks.

To see this traditional

lines view of the boat, select the View-Lines View command. Note that at any

time, you can print the current view using the File-Print command. The default

is to scale the view to maximize its display on your printer. You can also

control the scale factor of the output and plot all the way up to full size.

Before I start to edit

the shape of the boat, I’m going to turn off the automatic display of the lines

(PlaneCuts-Display Lines-All Lines OFF command) and display one of the 3

standard views of the hull. For this example, I will use the profile view of

the boat.

To begin editing the

shape, you need to select the Move Point button on the toolbar. This is the

button showing the four arrows pointing in different directions. I call this

the “rough” shaping part of the design process. This is not the time yet for

detailed shaping and fairing or smoothing.

Once the Move Point

command has been selected, you can select and drag any edit point on the boat.

An edit point is defined by a little square located at the intersections of all

curves (rows and columns) on the surface. Notice that each surface of the hull

is defined with only two rows (the top surface has the sheer and chine rows and

the bottom surface has the chine and profile or fairbody rows). Also note that

each surface is made up of only three columns (one at the bow, one at amidships

and one at the transom). For the NURB surfaces that are used to define these

surfaces, the rows and columns that define their shapes can be moved into any

position you want. However, it is best if you try to follow some basic rules

and terminology. For example, we call the curves that go along the length of

the boat the “rows” and the curves that go vertically the “columns”. These

definitions help us explain how to use the program. In addition, it is best if

you try to use the fewest rows and columns as possible (this makes it easier to

smooth or fair the hull) and try to keep a relatively even spacing of the rows

and columns (this avoids unwanted wiggles or bumps in the surface).

The CreateBoat command

creates a boat with the desired principal dimensions using the fewest rows and

columns as possible. The initial shape of the boat is very simple, but the

expectation is that you will be adding in more rows and columns to create your

desired shape. (There is another tutorial that goes into detail about the whole

hull design, shaping, and fairing process.)

OK, where were we? Oh

yes, Move Point. Once this command is selected, you can proceed to grab and

drag any point on the model. (Remember the Undo command if you make any

mistakes!) In the example below, I grabbed the amidships sheer edit point and

moved it much higher. Keep in mind that these are NURB surfaces and that any

change in shape in one direction affects the shape in all directions. This

means that the 3D model remains complete and exact.

Note that if you move an

edit point on the chine curve (common to both surfaces) then both of the

surfaces move together and do not split apart. Of course (!) you say? Well, you

might be surprised to find that many (most?) CAD programs can’t move both

surfaces at the same time!?! Our program sets up a geometric relationship

between the two surfaces so that if you move a common point on both surfaces,

then both surfaces move at the same time.

Also, remember that you do not have to “select” any geometry (like in

many CAD programs) before you can edit its shape. Once you select the Move

Point command, you can proceed to (and

continue to) move any edit point on the model.

Once you move a point on

the hull, try looking at the hull in all views, including the Render View, as

shown below.

The Render View should

reinforce the concept that the NURB surfaces are true 3D surfaces that

completely define the shape of the hull.

All you have to do is to shape and fair the hull surface.

I won’t go into the

whole shape designing process here since it is covered in detail in another

tutorial. I will just say that the process involves two phases: one is the

rough fairing portion that uses the Move Point command and the commands to add

additional rows and columns in the boat. The second phase involves using the

curvature curves (K-curves) to do the final fairing or smoothing of the boat.

Before I continue, I

want to Undo the change to the sheer curve that I just made.

What I do want to show

here, however, is the process of adding another chine to the boat. (I hope you

didn’t wait until this point to find out that you are not stuck with the single

chine that CreateBoat gives you.) The first thing you should do is to display

the “Right” or section or bodyplan view of the boat on the screen.

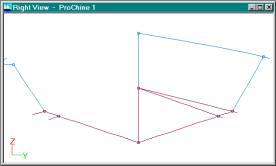

For this example, I want

to add a horizontal chine step to the boat. This can be done with just a few

commands. The first one is the Surf-Add Row/Col-Add Row/Col Knuckle command.

This command allows you to add a chine “row” to the hull in one step. What it

will actually do is to split a surface into two surfaces at your picked point.

After you select this

command, position the cursor on the amidships column (station, if you want),

just below the chine and click the left mouse button. You should see something

like this above. The program has split the bottom surface into two portions at

the newly inserted row.

The next step is to

merge the forward end of the new chine step row with the forward end of the

original chine. This is done with the Edit-Merge Pnt To Pnt command. When you

pick this command, it will display the following on the status line:

“Pick the point to

merge”

Pick the forward-most

edit point on the new chine row.

The next message will

be:

“Pick the merge to

point”

Pick the forward-most

edit point on the old chine row. Now the two points are tied together and you

can use the Move Point command to move them both at the same time. The points

will stay merged together unless you specifically un-merge them.

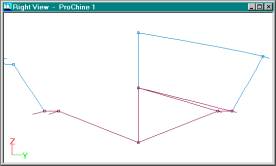

Since I want to have a

perfectly horizontal chine step, I want to move the inside chine edit points to

have the same height or ‘Z’ value as their associated outside chine points.

There is a quick way to do this with the Edit-Match Pnt-Z Match command. This

command allows you to set the first picked edit point to the same ‘Z’ value as

the second picked point. The picture above shows the result of using this

command on the middle and aft inner chine edit points.

Adding a new chine takes

only a minute or two. The Render View above shows the result of adding a

horizontal step into the boat. Of course, I really needed to talk about

creating the proper shape and width of the step, but this tutorial is getting

to be long enough. In real life, one would probably spend quite a bit of time

on the hull shape before adding the inside chine step. It is much easier to

shape the hull without the inside chine than with the inside chine.

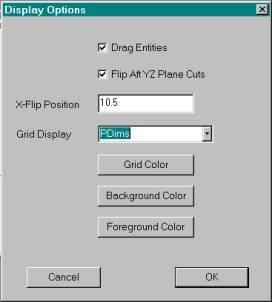

As you design the boat,

you might want to see a grid that defines the original principal dimensions

that you entered in the CreateBoat dialog box. We call these the “target”

values since those are the numbers you entered, but the program allows you to

change the shape to any size that you want. This is done by setting a value in

the Options-Display Options dialog box, as shown below.

To draw the principal

dimensions on each view, change the Grid Display menu to “Pdims” for principal

dimensions. After you pick the OK button, you will see something like what is

shown below.

The green line is the

target waterline. Of course, you don’t know where it will float, but many

designers like to see where they “hope” it will float. If you want to change

any of these target dimensions, you can do so in the File-Design Data dialog

box.

At any time during the

design process, you can calculate the hydrostatics, stability and resistance of

the boat. This will allow you change the shape of the boat early in the design

process to make sure that the target weight or displacement of the boat matches

the desired waterline location.

The hydrostatics are

calculated using the defined (PlaneCut) stations, so you must make sure that

there are “enough” stations (10-25) defined along the length of the boat. Also,

the program does not require you to close off all portions of the hull with

surfaces. For example, this boat does not have a deck or a transom. The program

will, however, close off the deck when creating the stations to use for the

calculations. Since this is not an exact process (the program may have to make

some educated guesses), then you must check to see if the stations that will be

used for the calculations look OK. This is done with the Calcs-Hydro-Draw

Stations command. When you pick this command, you will see the stations that

will be used for the hydrostatics calculations drawn in purple, as shown below.

You can rotate the boat

and zoom in to make sure that these stations look correct and are located from

the front of the boat all the way to the transom. Remember that the

calculations are done using these stations, so, if they look good and they

cover the full length of the hull, then you know the calculations will be

accurate. (Note that our calculation routines have been developed over 25+

years and have been tested on boats of all sizes and shapes.)

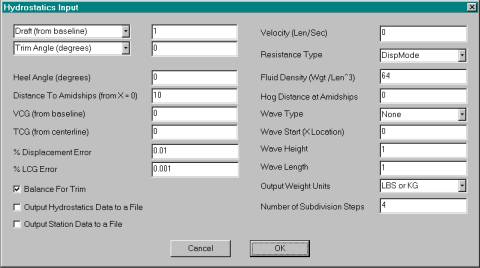

After you check out the

stations and they look OK, select the Calc-Hydro-Hydro Input+Calc command to

display the Hydrostatics Input dialog screen shown below.

I won’t explain all of

the options since our goal is to show you just a little bit about how the program

works. There are four different ways to

do the calculation. The first is to enter a draft (distance from the baseline

at amidships) and a trim angle. The second is to enter a draft and LCG

(longitudinal center of gravity). The third is to enter a displacement and trim

angle. The fourth is to enter a displacement and LCG. In the early stages of

design, most designers use the target draft and a trim of zero and that is what

is filled in here in the dialog box. Later in the design process, after you

have put together a detailed weight and center of gravity study, you will

probably enter the displacement, LCG, and VCG values and see where the program

says the boat will float.

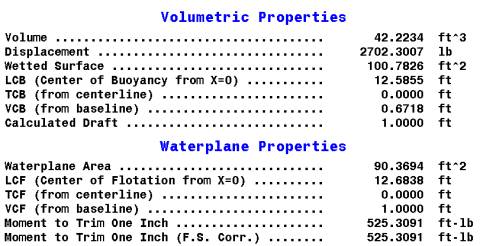

Just for the sake of the

example, use the existing input values and just pick the OK button. You should

see something like what is shown below (a partial listing of the results).

There are actually over

35 different values that are calculated and displayed. You can even output many

different sectional area data values that you can import into a spreadsheet for

further analysis. You might notice a number of calculated values that are

unfamiliar, like “Moment to Trim One Inch”.

Since we are doing the calculations, we figured that we should provide

as many values as possible, even if they are useful for only a few designers.

Also note that if you enter a heel angle, the

program will first do the calculation in the upright condition and then use the

calculated displacement and LCB to determine where the boat will float when it

is heeled over. In other words, the program will heel the boat to the desired

angle and then automatically sink and trim the boat to find the balance

condition that matches the upright condition displacement and LCB.

The program also

provides four different types of resistance calculations, but you have to enter

a target speed or velocity. One type of resistance is for canoes and kayaks

(Kaper), one is for sailboats (Delft), one is for planning powerboats in the

pre-planing condition (DispMode), and one is for large ships (Holtrop). Keep in

mind that these are “empirical” calculations whose results may not be perfectly

accurate, since they are trying to determine a very complicated result. They

are actually better at comparing boat ‘A’ with boat ‘B’ (a relative comparison),

rather determining the exact resistance of the boat. Also note that these resistance calculations are based on the

values of the boat at the current hydrostatic balance condition, using

calculated values like the waterline length, displacement, wetted surface and

half angle of entrance of the waterline.

After looking at the

hydrostatics values, you can select another hull view toolbar button to change

the view.

The next big area of the

program to investigate is plate development or layout. For many, the ability to

plot or cut full-size the frames and plates is the main reason for using this

program. If you don’t know too much

about plate development and layout, I would suggest that you read our other

article on this subject. It talks about the difference between developable,

expandable, and buildable. Many hulls may not be perfectly developable, but

they are buildable.

This program gives you

two ways to create and check for developable surfaces. One way, familiar to

many, is to use “ruling lines” that connect two curves, such as a chine curve

and a sheer curve. The ruling line method is described in another one of our

tutorials and will not be discussed here. Here, we will look at the process of

unwrapping or developing a surface and do some checks to see how close a

surface is to being perfectly developable.

The program will try to

unwrap or flatten any surface. All you have to do is to select the

Develop-Develop Plate command and pick along any row or column of any surface

(don’t pick along a common edge between two surfaces). Even if the surface has

a lot of twist or double curvature, the program will try to flatten it out. The

program uses a finite element type of calculation to flatten the plate and

determine the stretch or strain in the plate. This is a very sophisticated

calculation and is not just a simple triangulation-type of layout.

There are some surfaces

that have too much double curvature and the layout will fail. If this happens,

it means that the surface has too much curvature to unwrap and you will have to

break down the surface into smaller pieces. If you are using our

full-capability ProSurf program, then there are commands to attach curves to

surfaces to define the sub-portions of the surface that you want to develop (butt

and seam lines for ships). You would then create sub-surface patches on top of

the larger, doubly curved surface that you could develop.

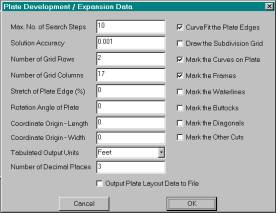

OK, back to the

example. Pick a row or column point on

the top surface of the boat. You will

see the following dialog box with many input fields that are all filled in with

default values.

Again, I won’t go into

details about all of the fields, but you can see that there are many options.

Just leave the default values and pick the OK button to see what you get. You

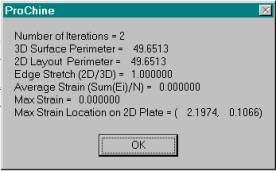

should see the results box below.

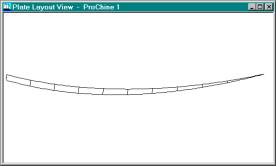

The program uses a

search technique to find the solution to the flattening problem. The default

condition is to make sure that the 2D perimeter of the pattern matches the 3D

perimeter of the 3D surface. The box also gives you some idea about the amount

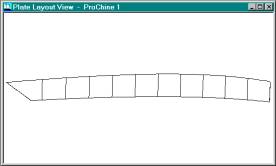

of stretch in the middle of the plate. After you pick the OK button, you should

see something like what is shown below.

This shows the 2D

pattern of the top plate marked with all of the defined station locations.

Remember that some designers will change from defining stations to defining

frames (using PlaneCuts) during the later stages of design so that these

markings will show frame locations rather than station locations. The pattern

is rotated to minimize the amount of paper that would be used when the pattern

is cut out.

This view of the pattern

can be printed or plotted out at a scale factor, plotted out full size, or

output to various types of file formats to either bring to another location for

plotting or for CNC cutting.

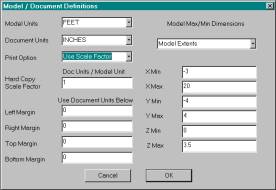

To plot at a scale

factor or at full size, you need to go to the Options-Mod/Doc Definitions

dialog box, as shown below.

This example shows that

the program will use the defined scale factor and the defined scale factor is

one inch equals one foot. If you want to plot full size, then you need to

change the document units to feet. Then, the scale factor will be one foot

equals one foot. WARNING! Always use the File-Print Preview command to see if

and how the program will break the drawing into pieces (pagination) for

drawing. If you get the scale factor wrong, then the program might want to plot

out a thousand pages! The program “asks” Windows about the printer or plotter

that is attached to the system and what size of paper it is using. Then, the

program figures out how many pages are required to plot the drawing at the

selected scale factor. Note that the default print or plot size is to use

whatever scale factor will fit the entire drawing on your paper (one sheet).

For output to a file,

you need to use one of the options in the File-Data File Output submenu. The

most common one is to use the 2D DXF file output. Most CNC cutting systems can

read these files. If you are interested in doing this, then contact the place

that will be doing the cutting (or plotting) and see what software they have

and what transfer geometry file formats they accept.

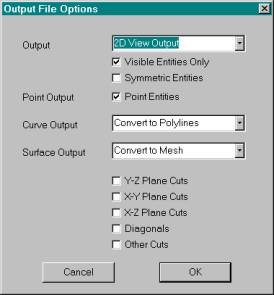

To output to a 2D DXF

file, first, make sure that the 2D pattern is shown in the current view window.

Next, select the File-Data File Output-DXF File Output command to see the

dialog box shown above. Now, make sure that the top field is set to “2D View

Output” rather than the 3D output option. This will guarantee that the program

will output the 2D view shown in the current view window. Once you select the

OK button, Windows will display a file output dialog box that you can use to

name the file and select the destination folder.

Well, we flattened this

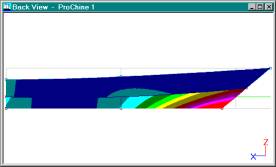

plate, but how do we know if it is developable or buildable? We can use the Surf-K_Patch-Kpat

All command to turn on the display of the Gaussian curvature. If you select

this command and redraw the screen, you will see the following.

The dark blue indicates

a Gaussian curvature of zero, which means that that portion of the hull is

perfectly developable. (Gaussian curvature is a way of calculating how much

double curvature a surface has.) If the Gaussian curvature is zero, it means

that the surface has at least one direction that is flat at that point. As the

colors change to light blue, to green to yellow, and then to red, the amount of

double curvature increases. We have found that a boat is buildable if the

colors remain in the dark blue, light blue or light green regions. This means

that (within reason) you can twist or torture(?) the plate material to fit.

Please don’t hold us to this criteria, since everything depend on the type of

material, its thickness, and its dimensions. We usually tell people that if

there is any question at all, build a small model to see if everything will

fit. This is especially important if you CNC cut out both the frames and the

plates. You may wish to leave extra scrap material along one of the edges of

the plate. (See our other article that goes into more detail about this

developable vs. buildable question.)

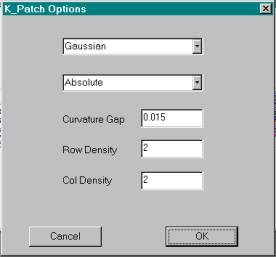

Note that this picture

isn’t filled in completely. This is because the Gaussian curvature calculation

is done for each pixel of the boat and we wanted to make sure it is reasonably

fast. If you want to see what it would look like filled in completely, then

select the Surf-K_Patch-Kpat Options to see the dialog box below.

Change the Row and Col

Densities to 1 and select the OK button. You may have to use the View-ReDraw

View command to see what is shown below.

As you can see, it looks

better, but takes longer to draw. Note that the top plate is almost perfectly

developable, but there is a good amount of double curvature in the front end of

the bottom plate. If you are trying to create a developable boat, then you

would have to change the shape of the bottom surface and recheck with the

Gaussian curvature display. Since the Gaussian curvature cannot be dynamically

redrawn as you are dragging points on the surface, then you may want to look

into our “ruling line” method for creating developable surfaces. That technique

allows you to dynamically see the amount of twist in the surface while you are

dragging or moving the edit points. (See the other ruling line tutorial.)

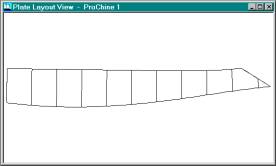

If you use the develop

plate command on the step surface, this is what you will see.

If you looked at the

Gaussian curvature of this surface, you would see that it was developable and

this pattern should be accurate.

This is the result of

developing the bottom surface.

It can be done, but you

wouldn’t want to use the results, since it requires a lot of stretching. Just

because the program can flatten the 3D surface into a 2D pattern doesn’t mean

that you want to use the result. [I can, however think of one exception.

Perhaps you are trying to cut out some very stretchy material that you want to

use to protect the bottom of the hull.] In any case, we have to leave it up to

you to decide when to use a particular 2D pattern.

Before I end this

example, I want to make sure you know that the program created a deck surface

in the CreateBoat process. It was a simple straight across surface and it was

turned off. If you select the Surf-Draw All Surfaces command and turn on the

Render View, you should see something like what you see below.

Thank you for going through

this tutorial. Hopefully, it hasn’t been too long (or too short) or boring.

There are other tutorials and articles that can continue on from here. Feel

free to contact us if you have any questions or comments.